-40%

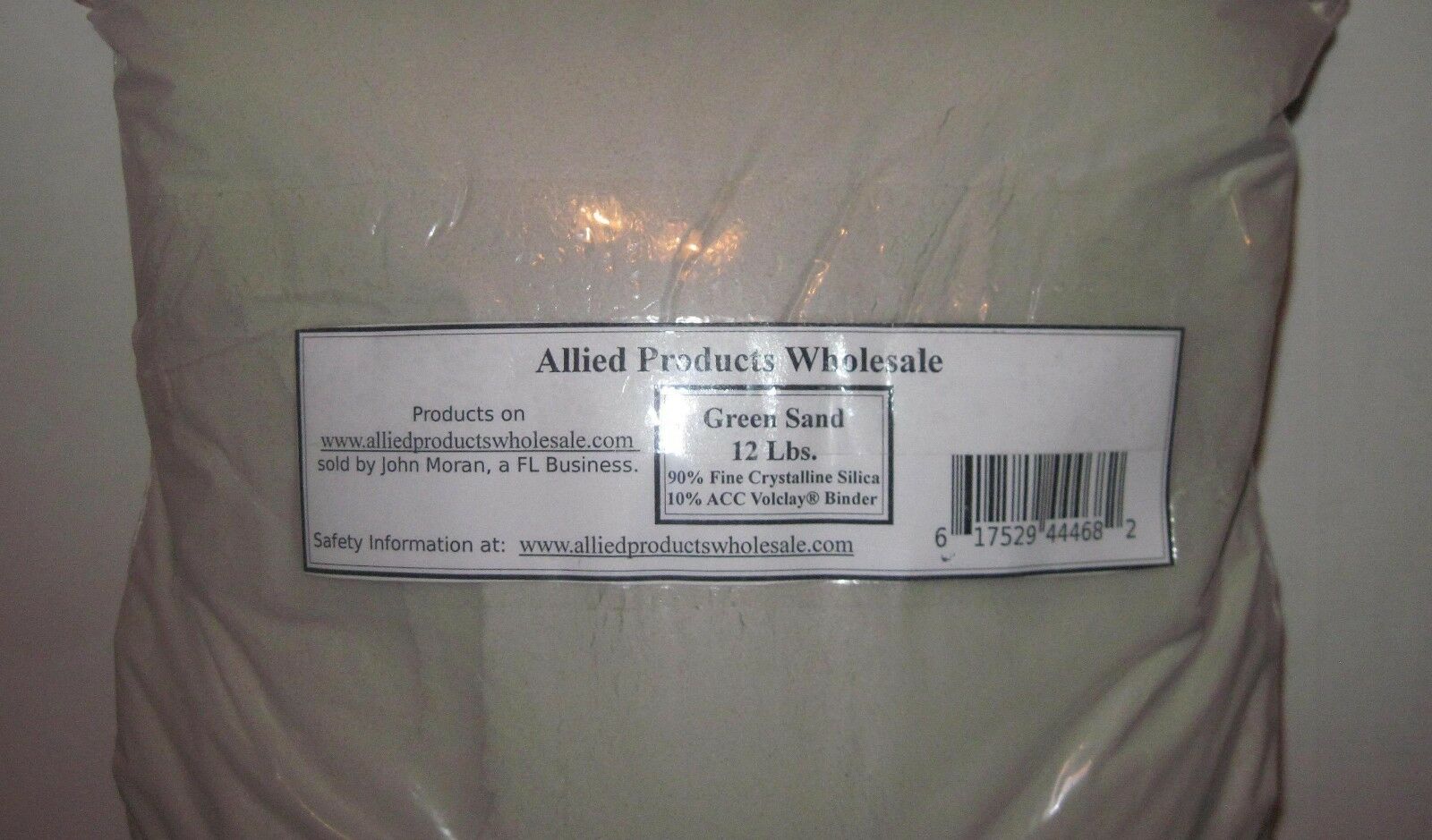

Professional Petrobond Casting Sand (FINE MESH) jewelry and precision 24LB BOX

$ 30.62

- Description

- Size Guide

Description

Professional Petrobond Casting Sand (FINE MESH) jewelry and precision 25LBProfessional Petrobond Casting Sand (FINE MESH) jewelry and precision 24LB BOX

[link removed]

TETON-BOND 130 PROFESSIONAL PETROBOND FOUNDRY SAND (24lb)

Teton-Bond 130 is a premium-quality, oil-bonded foundry sand formulated especially for precision metal casting applications in the small shop. When properly used, it can provide near die-cast surface finishes and pick up fine details normally only attainable by other more involved processes.

Product Highlights:

Use for precision casting of jewelry, decorative items, and mechanical parts

Premium 130 mesh raw sand and genuine Petrobond additives provide excellent surface finish

100% Ready To Use--premulled using industrial batch mullers

Professionally formulated, mulled, and batch quality monitored

Reusable (small amount of burnt crust should be discarded)

Troubleshooting

Cold Sand Issues and fixes (Dry and Powdery Sand)

Oil-bonded sand is typically temperature sensitive and can become dry and powdery if used or stored in cold conditions. Teton-Bond is no exception. For best results, Teton-Bond should be stored and used at 60F and above. Generally, if the sand is cold and exhibiting a lack of cohesiveness, simply allowing it to warm to near room temp before use will fix the issue.

Also, if Teton-Bond is stored in the extreme cold for a period of time it may change character in a more persistent manner. In this case, simply warming to room temp may not be sufficient to recondition the sand. If this occurs, heating the sand to approx 90-100F will fully restore properties (this trick also works to revitalize the sand when it is getting near replacement after long-term use). For small amounts of sand this heating step can be accomplished by placing the sand in several sealed plastic bags and submerging in a bowl of hot water.

Note that we do not add excessive oil to our sand to counteract its tendency to be temperature-sensitive. This is because additional oil beyond that specified in the Petrobond blending specification degrades casting surface finish.

What is correct texture?

Petrobond sand should never have a clay-like, sticky consistency when manufactured correctly--sticky means too much oil. Rather, it should be fairly free-flowing when broken up and then clump very aggressively when pushed into the mold or squeezed in the hand.

Black Crust and Sand Reuse

Black crust around castings is to be expected with all oil-bonded foundry sands. However, not all of the black sand needs to be discarded. Only the portion of black/grey sand that has a "crispy" texture needs to be removed. Basically, what happens is that the binder and oil from that part of the sand is burnt and thus it will no longer stick together. Note that it is very normal for a petrobond sand pile to grow darker with use.

It may be desirable to keep some new, fresh sand on hand for use directly against the pattern in cases where extremely high surface finish is required.

Loss of Detail related to pattern withdraw

Use of a high-quality, foundry-grade pattern/parting compound is necessary to get the best out of Petrobond sand. Our Teton-Part(TM) or similar should be used instead of cheap (or no) parting compounds (talc, flour, silica dust, etc). Proper foundry parting compounds maximize detail reproduction from any given pattern and often allow patterns that are substandard to be used successfully.

Safety:

This sand contains crystalline silica and can be very detrimental to your long-term health if improperly used/handled/stored. Read complete SDS and product labels prior to use (this text is not intended as a substitute for the physical warning label).

Foundry work is dangerous--please take precautions to educate and protect yourself from hazards.

Disclaimer

Our products are intended for sale to industrial and commercial customers. We request that customers inspect and test our products before use and satisfy themselves as to contents and suitability. Nothing herein shall constitute a warranty, expressed or implied, including any warranty or merchant-ability or fitness. The exclusive remedy for all proven claims is replacement of our materials and in no event shall we be liable for special, incidental, or consequential damages.

Listing and template services provided by inkFrog